1. Product Introduction

The lightning arresters produced by Zhongwei Electric can meet all application requirements and comply with the latest versions of IEEE C62.11 or IEC 60099-4. Polymer and ceramic lightning arresters can be selected, and they also provide different levels of energy and mechanical capabilities to meet the specific needs of each customer. Zhongwei Electric lightning arresters are installed in various environments around the world and continue to provide excellent equipment protection.

Metal oxide surge arresters use zinc oxide resistors with excellent nonlinear volt ampere characteristics, which have the characteristics of good steep wave response, strong current carrying capacity, large energy absorption, low residual voltage, and large protection margin. This makes the protection margin of steep wave impulse residual voltage, lightning operation impulse residual voltage, and operation impulse residual voltage nearly consistent, providing the best protection for electrical equipment insulation. It has replaced traditional silicon carbide lightning arresters and become the mainstream product for overvoltage protection.

The working principle of lightning arrester - When the lightning arrester is placed on a substation or transmission or distribution line, it can protect the connected equipment from various types of voltage surges. At normal operating voltage, lightning arresters exhibit very high impedance. When high voltage surges caused by lightning strikes or switch activities occur, lightning arresters quickly transition to very low impedance.

Surge arresters are usually connected from one line to another, passing through the equipment to be protected, and then providing a bypass for surge currents, while clamping the line to ground voltage to a level far below the equipment insulation withstand level (BIL or BSL). Once the surge passes, the lightning arrester will return to its original state, and the system will survive the event without interruption.

2. Normal usage conditions

(1) Suitable for indoor and outdoor use;

(2) Environmental temperature: not lower than -40 ℃, not higher than+40 ℃;

(3) Altitude not exceeding 3000m;

(4) Grid frequency: 48-52Hz (50Hz system), 48-62Hz (60Hz system);

(5) The power frequency voltage applied between the terminals of the lightning arrester for a long time should not exceed the continuous operating voltage of the lightning arrester;

(6) Areas with seismic intensity of 7 degrees or below;

(7) The maximum wind speed shall not exceed 35m/s.

3. Ordering requirements

(1) Product model;

(2) Structural type (including gap, suspension, seat, plug-in, installation method);

(3) Environmental requirements (pollution, altitude);

(4) Required attachments (counters, monitors, disconnectors, insulation brackets, etc.);

(5) APP intelligent monitoring and wireless transmission;

(6) The product model displayed in the technical table is a regular product; Plateau type with letter: GY, anti fouling type with letter: W, fully insulated type with letter: Q;

(7) Maximum system voltage, system grounding method (effective grounding, impedance grounding, ungrounded), insulation level of protected equipment;

(8) The required scope of protection;

(9) The level and duration of power frequency overvoltage;

(10) The length of the line to be switched;

(11) The mechanical load that the lightning arrester will bear;

(12) Available line to ground fault current;

(13) Other special requirements.

Note:

(1) Lightning arresters manufactured according to the above conditions are called standard products. Beyond the normal usage conditions mentioned above, the user shall indicate it in the contract or sign a technical agreement as the basis for manufacturing, acceptance, and use.

(2) In addition to standard products, our factory can also provide high-altitude products for use in areas with different altitudes of 3000m and above; And use pollution resistant products with different creepage distances in heavily polluted areas.

4. Selection Overview

The lightning arrester should meet the following basic requirements:

Can withstand the continuous operating voltage of the system for a long time and can withstand transient overvoltages that may occur frequently for a short period of time. Under the action of overvoltage, its protection level meets the requirements of insulation level. Capable of withstanding the energy generated by discharge current under overvoltage. After overvoltage, it can quickly restore normal working condition.

4.1 Firstly, it is necessary to pay attention to the following key points

The first step is voltage level.

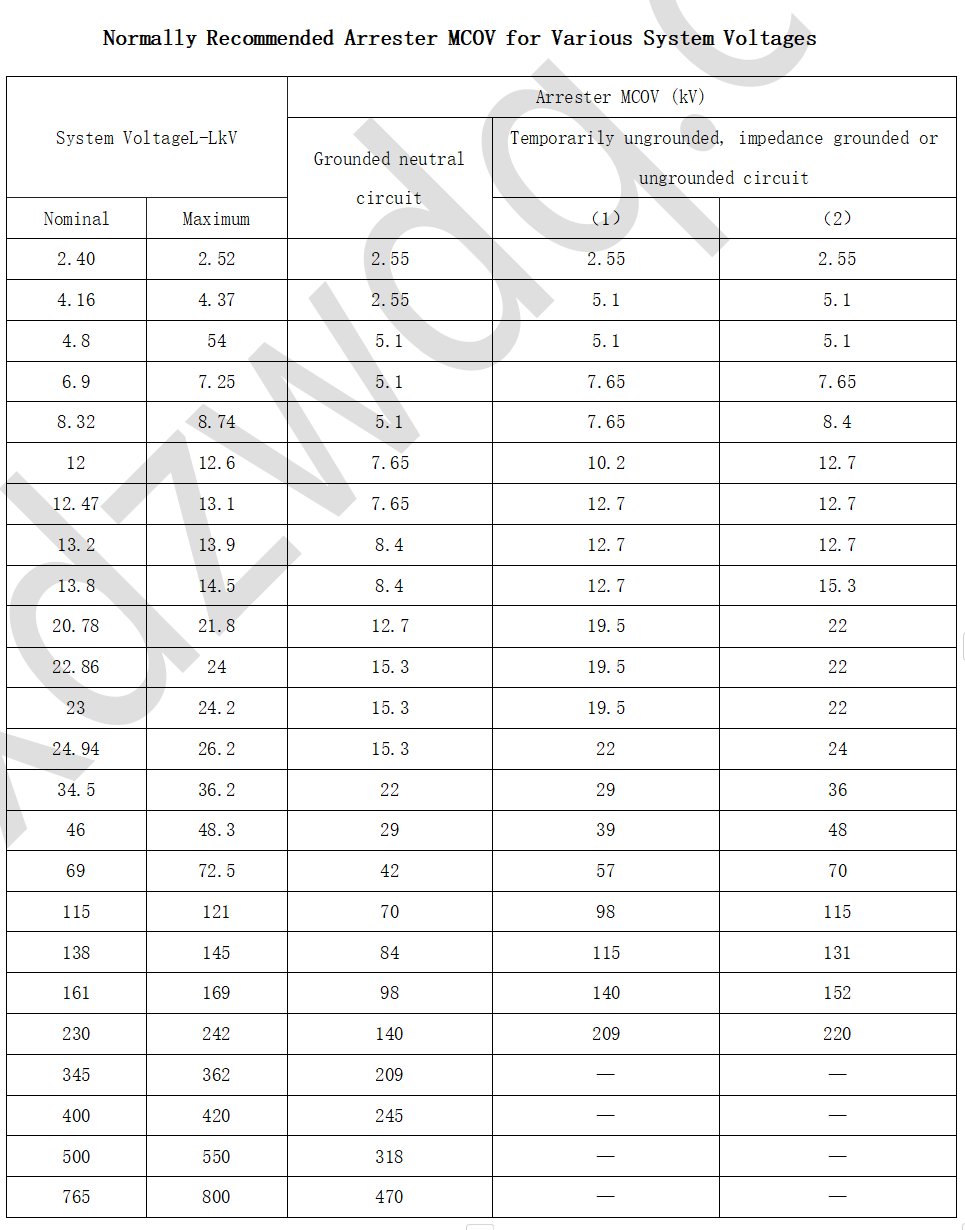

Domestic type: determined based on the nominal voltage of the system and the neutral grounding method.

Export type: Each voltage level is 3kV, selected according to the insulation coordination requirements of the equipment.

Step 2: Structural Features.

Gap free type: For regular use, there are corresponding gap free models available for various purposes.

Gap type: Only used in areas that require enhanced protection. (For example, line protection)

The third step is to protect the object.

Step 4: Place of use.

Conventional lightning arresters are universal for both indoor and outdoor use, and products with umbrella shaped designs that comply with regulations should be able to meet pollution prevention requirements of Class III and below.

If the pollution level exceeds level III, anti fouling products need to be used and the climbing distance needs to be calculated.

When the altitude exceeds 2000m, it is necessary to calculate the proportion of reinforced insulation and use high-altitude products.

4.2 Other selection matters

Advantages and disadvantages of ceramic lightning arresters.

Advantages: Durable, theoretically usable for 50 years without major accidents.

Disadvantages: Large and bulky, not conducive to installation, easily broken during transportation, prone to explosion and injury during use, and equipment.

Advantages and disadvantages of organic silicon polymer lightning arrester.

Advantages: High insulation, good heat dissipation, conducive to miniaturization and complete electrical use.

Disadvantage: The jacket has a lifespan issue, and the rubber ages after 10 years of use.

4.3 The most troublesome issues in the procurement of metal oxide overvoltage protectors

Lightning arrester is the fundamental equipment for insulation coordination in the entire power system. The design unit must determine the withstand voltage capability of all high-voltage electrical equipment in the system based on the performance of the lightning arrester, so the selection of its performance is of great significance. Below is a brief explanation of the most difficult structural, model, and parameter issues in the selection of metal oxide overvoltage protectors.

4.4 Important Parameters for Selection

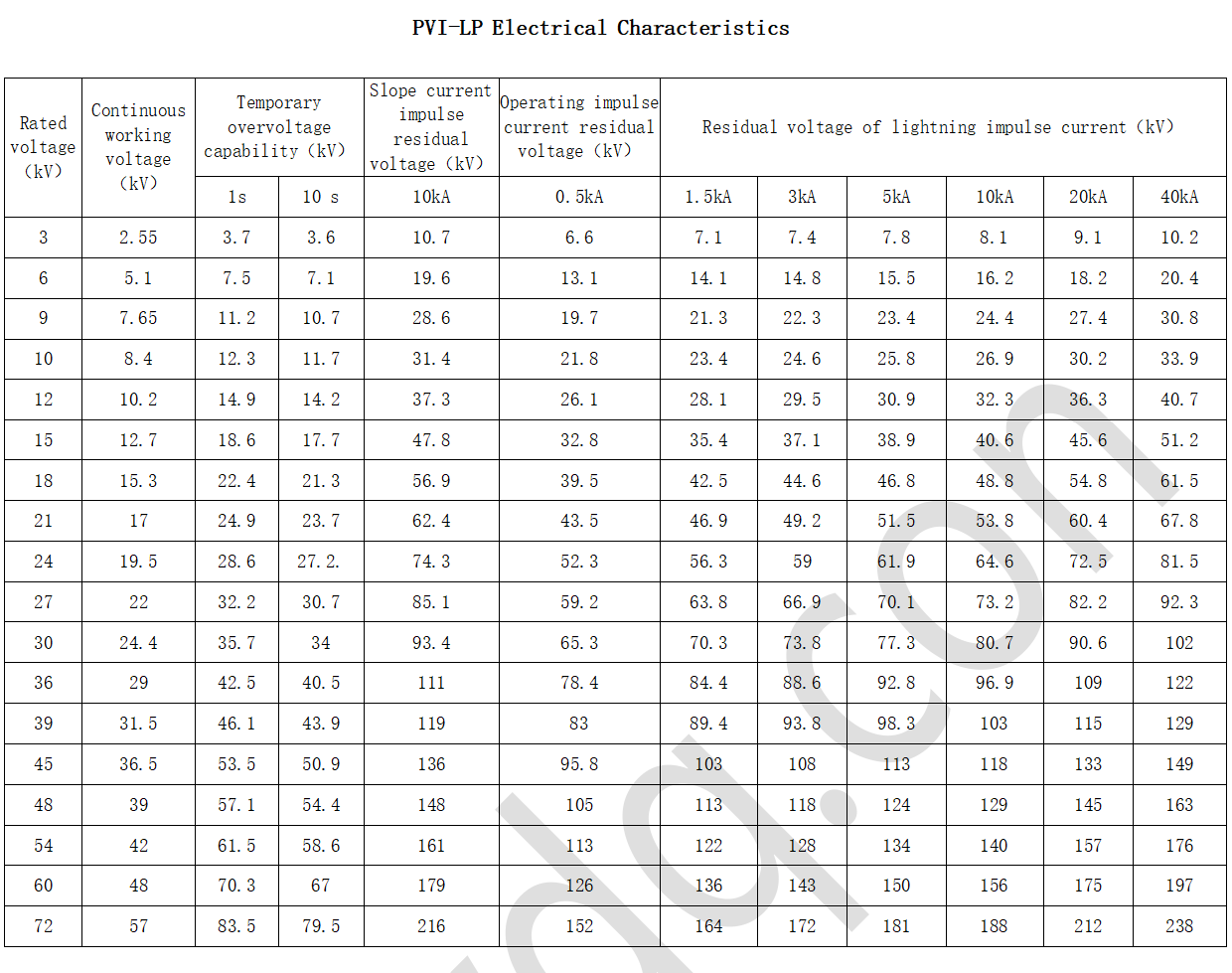

There are three most important parameters for lightning arresters. One is the rated voltage, one is the nominal residual voltage, and one is the energy absorption capacity. Let's take YH5WS-17/50 as an example to illustrate.

4.4.1 Rated voltage

17 in the above models represents the rated voltage. The definition of rated voltage is quite complex. As a non professional manufacturer, it can be simply understood as the effective value of overvoltage reaching around 17kV, and the lightning arrester will start working. This parameter cannot be too low, otherwise it may cause the lightning arrester to be overloaded and burned out. Although the old national standard defines the rated voltage as 12.7, the actual working value is still around 17, so there is a lot of controversy over the definition of the old national standard, and it is no longer promoted. So whether the rated voltage is 17 or 16.5, 17.5, is actually the same performance level, both of which comply with the national standard definition of Class 17 products. As for why there are things like 17.5 and 16.5, it is because each manufacturer has slight differences in specific parameters and unique sales strategies for the models shown in the picture.

4.4.2 Nominal residual voltage

The 50 in the above models represents the nominal residual voltage of lightning, which can be simply understood as the lightning arrester being able to limit the peak overvoltage to at least 50kV during the most severe lightning strike. This parameter is actually the most important parameter of the lightning arrester, because the foundation of the insulation coordination of the entire system is here. We keep saying that reducing residual voltage is good because reducing the residual voltage of lightning arresters is equivalent to improving the safety margin of all high-voltage electrical appliances in the system. However, reducing residual voltage is limited by the performance of zinc oxide resistors themselves, and there is a limit. Although products with gaps can further reduce residual pressure, they are not infinitely reduced and there is also a bottom limit. If some manufacturers claim that their product residual pressure is lower than other manufacturers, it is recommended not to purchase.

4.4.3 Energy absorption capacity

When the lightning arrester is working, due to the high current of kA level passing through, the resistor will heat up significantly. If it cannot withstand it, it will cause damage or even explosion. Therefore, the energy absorption capacity of lightning arresters is an important parameter. Export type products, express this capability in terms of how many kJ/kV; Domestic products are expressed in terms of the square wave current carrying capacity A, and the higher this value, the greater the current that the lightning arrester can withstand without damage, and the better its performance. This ability is directly related to the diameter of the resistor, just like when purchasing copper wire, the thicker the wire, the greater the current that can flow through it. When the formula is similar, the larger the resistor, the stronger the natural square wave current passing ability.

4.5 Scope of Application

AC gapless metal oxide surge arresters are used to protect the insulation of AC transmission and transformation equipment from lightning overvoltage and operational overvoltage damage. Suitable for overvoltage protection of transformers, transmission lines, distribution panels, switchgear, power metering boxes, vacuum switches, parallel compensating capacitors, rotating motors, and semiconductor devices.

4.5.1 Characteristics

The zinc oxide lightning arrester has a high current carrying capacity

This is mainly reflected in the ability of lightning arresters to absorb various lightning overvoltages, power frequency transient overvoltages, and operational overvoltages. The current carrying capacity of zinc oxide lightning arrester fully meets or even exceeds the requirements of national standards. The discharge level, energy absorption capacity, 4/10 nanosecond high current impulse withstand, 2ms square wave current carrying capacity and other indicators of the line have reached the leading level in China.

Excellent protection characteristics of zinc oxide lightning arrester

Zinc oxide lightning arrester is an electrical product used to protect various electrical equipment in the power system from overvoltage damage, with good protection performance. Due to the excellent nonlinear volt ampere characteristics of zinc oxide valve plates, only a few hundred microamperes of current can pass through under normal operating voltage, making it easy to design as a gapless structure and possessing the characteristics of good protection performance, light weight, and small size. When overvoltage invades, the current flowing through the valve plate rapidly increases, while limiting the amplitude of the overvoltage and releasing its energy. Afterwards, the zinc oxide valve plate returns to a high resistance state, allowing the power system to operate normally.

The sealing performance of zinc oxide lightning arrester is good

The lightning arrester components are made of high-quality composite jackets with good aging performance and air tightness. Measures such as controlling the compression of the sealing ring and applying sealant are taken. The ceramic jacket is used as the sealing material to ensure reliable sealing and stable performance of the lightning arrester.

Mechanical properties of zinc oxide lightning arrester

4.5.2 Mainly consider the following three factors: the seismic force borne, the maximum wind pressure acting on the lightning arrester, and the maximum allowable tensile force of the conductor borne by the top of the lightning arrester.

Good pollution removal performance of zinc oxide lightning arrester

The gapless zinc oxide lightning arrester has high resistance to pollution, and the current national standard specifies a creepage distance level of:

Level II moderately polluted areas: creepage distance of 20mm/kV, Level III heavily polluted areas: creepage distance of 25mm/kV, Level IV extremely heavily polluted areas: creepage distance of 31mm/kV

High operational reliability of zinc oxide lightning arrester

The reliability of long-term operation depends on the quality of the product and whether the product selection is reasonable. There are three main aspects that affect its product quality:

The rationality of the overall structure of the lightning arrester, the volt ampere characteristics and aging resistance of the zinc oxide valve plate, and the sealing performance of the lightning arrester.

Power frequency withstand capability

Due to various reasons such as single-phase grounding, long line capacitance effect, and load shedding in the power system, it can cause an increase in power frequency voltage or generate transient overvoltage with high amplitude. Lightning arresters have the ability to withstand a certain increase in power frequency voltage for a certain period of time.

5. Preventive testing methods

Before the product is put into operation and every year during use, preventive tests should be conducted:

(1) The preventive test method for gapless metal oxide surge arresters is:

a、 DC 1mA reference voltage test: Apply a DC voltage at both ends of the lightning arrester, and when the current flowing through the lightning arrester stabilizes at 1mA, read out the voltage value at this time, which should meet the specifications in the technical parameter table.

b、 Leakage current test: Apply 0.75 times the DC 1mA reference voltage value at both ends of the lightning arrester, and the current flowing through the lightning arrester should not exceed 50 μ A.

c、 Metal oxide surge arresters without gaps cannot undergo power frequency discharge voltage testing.

(2) Preventive testing method for metal oxide surge arresters with series gap:

a、 Power frequency discharge voltage test: Connect a current meter of 10A or more in series on the primary side of the test transformer. During the experiment, voltage should be uniformly applied from zero, and the ammeter should be observed. When there is a sudden change in the ammeter, it indicates gap discharge, and the voltage value at this time is the power frequency discharge voltage value. After each discharge, the power supply should be cut off within 0.2 seconds. The interval between every two experiments shall not be less than 10 seconds, and the measurement frequency shall be 3 times. The average value of the three times shall comply with the specified values in the technical parameter table.

b、 Conductance current test: Apply a direct current voltage at both ends of the lightning arrester, with the applied voltage value being the nominal system voltage of the lightning arrester. At this time, the current flowing through the lightning arrester should not exceed 20 μ A.

c、 Metal oxide surge arresters with series gap cannot undergo a 1mA DC reference voltage test.

(3) It is strictly prohibited to conduct insulation withstand tests on lightning arresters. When conducting insulation withstand tests on other equipment in the system, the lightning arrester and equipment connection must be disconnected.

(4) The lightning arrester shall not be inverted or tilted, and the composite umbrella skirt shall face downwards. The inclination of the lightning arrester shall not exceed 1.5% of the total height of the lightning arrester.

6. Installation and Storage

(1) During the process of packing, unpacking, transportation, storage, and installation, lightning arresters must be placed upright and not reversed, tilted, or transported. To avoid impact and collision of lightning arresters, especially the pressure plates at both ends of the main components should not be damaged. If "inversion" or "collision" is found, careful inspection should be carried out to confirm that the internal structure is not damaged before installation

use. If there is damage, it should be replaced.

(2) The speed for transporting lightning arresters by car shall not exceed 60km/h.

(3) Before installation and use, lightning arresters should be stored in a clean and dry room and should not be corroded by corrosive gases or liquids.

(4) The sealing of the lightning arrester is good. Therefore, without the permission of the manufacturer, users are not allowed to disassemble at will to avoid damaging the seal and causing internal moisture damage.

(5) Before and after installation and operation, as well as during regular inspections, lightning arresters must be carefully inspected and tested. The test results should be recorded in a dedicated manual for analysis and comparison. And serve as a reference for regular inspections. The recorded items should include the testing time, temperature, relative humidity, voltage, product number, rated voltage, and measurement data. The specific testing items include:

(6) Check the discharge counter or detector. Record the initial value when put into operation, and check the lightning arrester once a month or after rain in the future.

(7) Check the lightning arrester generally once a year. The focus of the inspection is on the tightness of bolts and nuts, whether the mating surface is dirty or damaged, the corrosion of components, and the tightness of high-voltage wires and grounding wires.

(8) Insulation resistance measurement is generally conducted once a year. Measurements should be taken on clear weather with a clean and dry synthetic surface. When measuring, the synthetic sleeve should be shielded. Use a 2500V megohmmeter to measure the insulation resistance value of the lightning arrester with a system voltage of 4-17kV, which should not be less than 1000M Ω; Measure the insulation resistance of lightning arresters with a system voltage above 51kV using a 5000V megohmmeter, which should not be less than 2500M Ω; And compare it with previous data.

(9) Measure the DC reference voltage of the lightning arrester at DC 1 mA and the microampere value at 0.75 times the DC 1 mA voltage (which should not exceed 50 μ A) using a high-voltage DC device (the DC voltage fluctuation part should not exceed ± 1.5%). For polluted areas, in addition to the above testing items, regular cleaning should also be carried out. Especially clean the surface of the synthetic sleeve and the sink with slotted gaskets.

(10) The standard length of 10kV, 20kV, and 35kV lightning arresters for fully insulated high-voltage insulated lines is 500mm, and the user can specify the length requirements as needed. During the use of high-voltage lines, it is prohibited to cross connect between phases, overlap, knot, or be close to other conductors. Effective national standard air insulation should be met to avoid aging of high-voltage lines, single-phase overlap with other conductors, breakdown of the insulation layer of high-voltage lines, or single-phase explosion. If the length of the high-voltage line is too long, the excess can be cut off as needed.

(11) It is recommended to choose multi strand tinned flat copper wire connection for grounding: the cross-sectional diameter of the wire is 6kV, 10kV, 20kV ≥ 10mm2, 35kV ≥ 16mm2, 110kV ≥ 25mm2.

(12) During the installation, handling, and relocation of high-voltage wires for metal oxide surge arresters, it is prohibited to pull or tie them.

(13) The lightning arrester shall not be inverted or tilted, and the composite umbrella skirt shall face downwards. The inclination of the lightning arrester shall not exceed 1.5% of the total height of the lightning arrester.

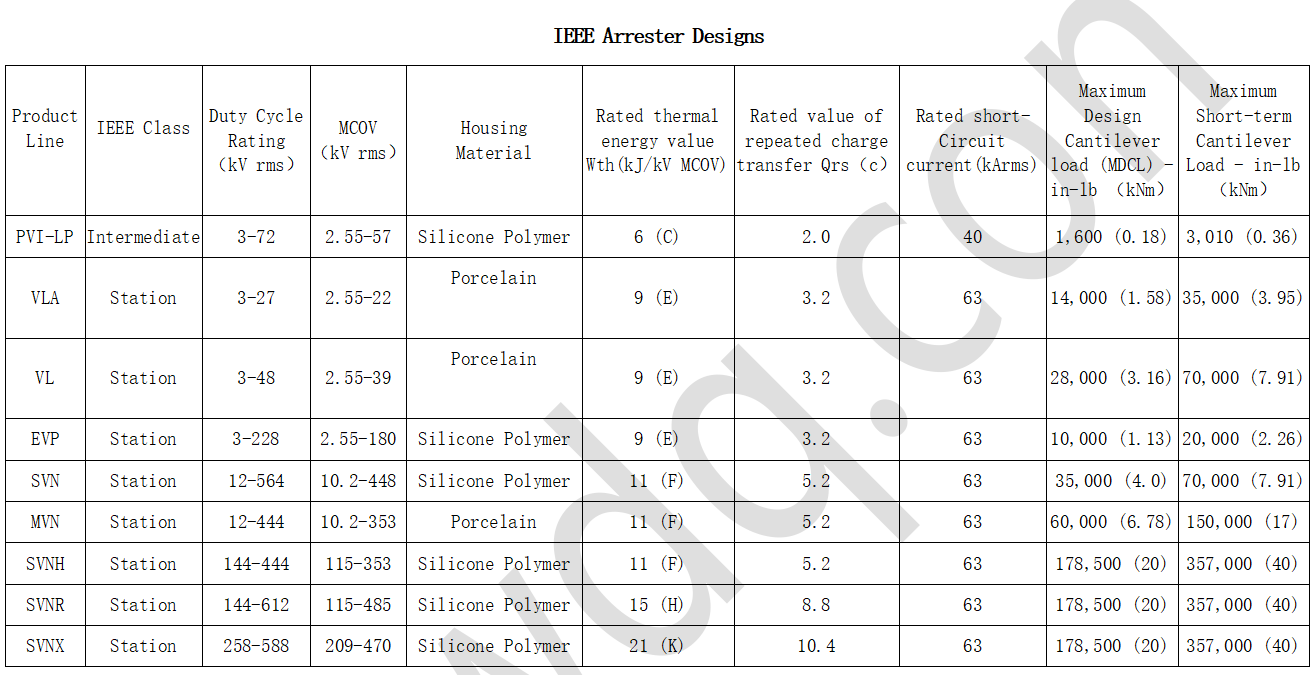

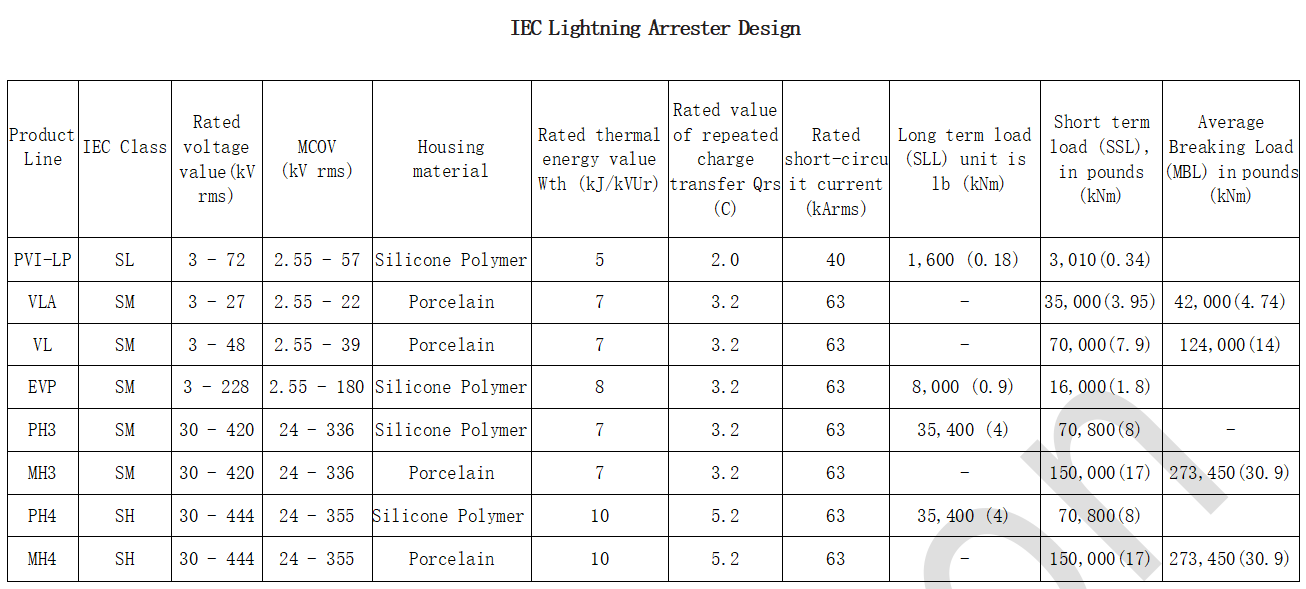

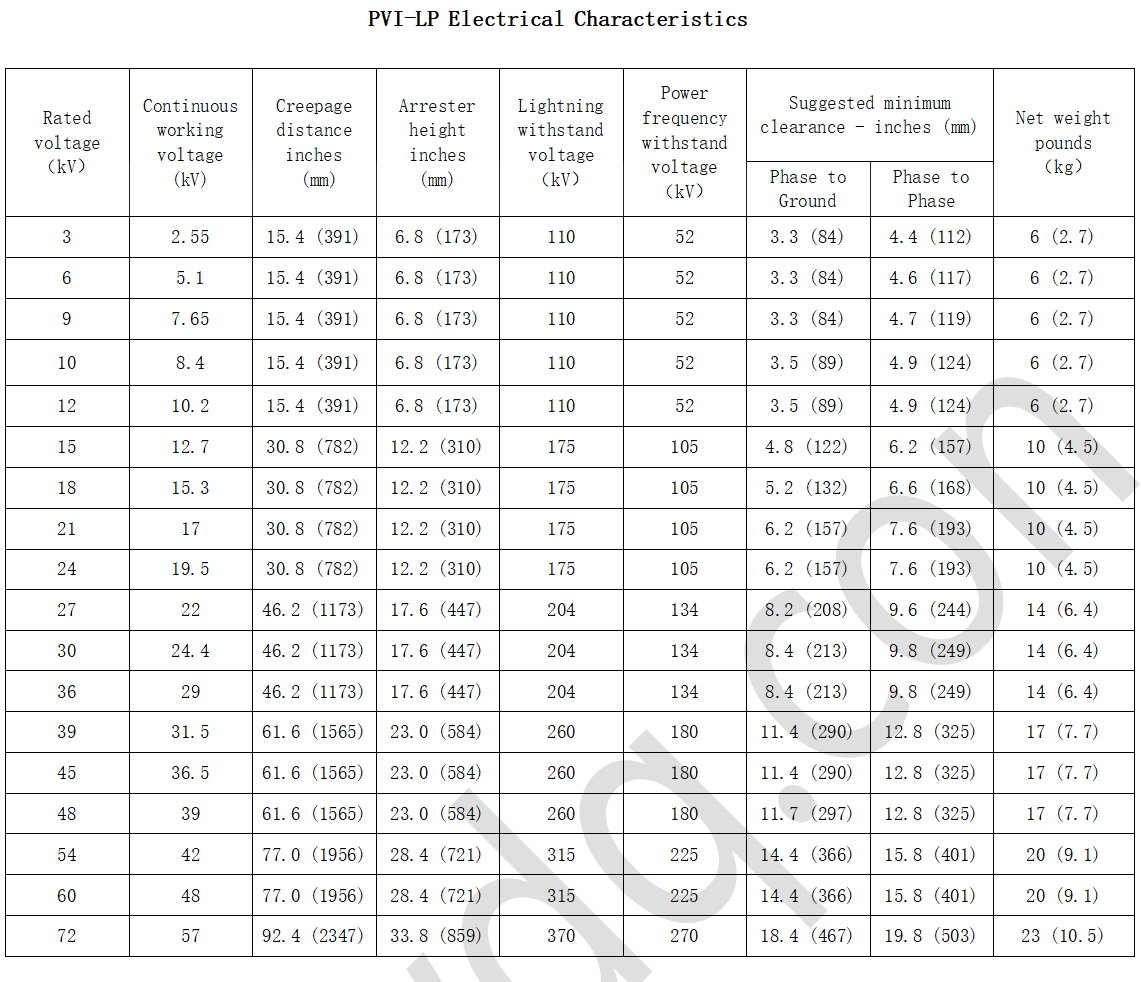

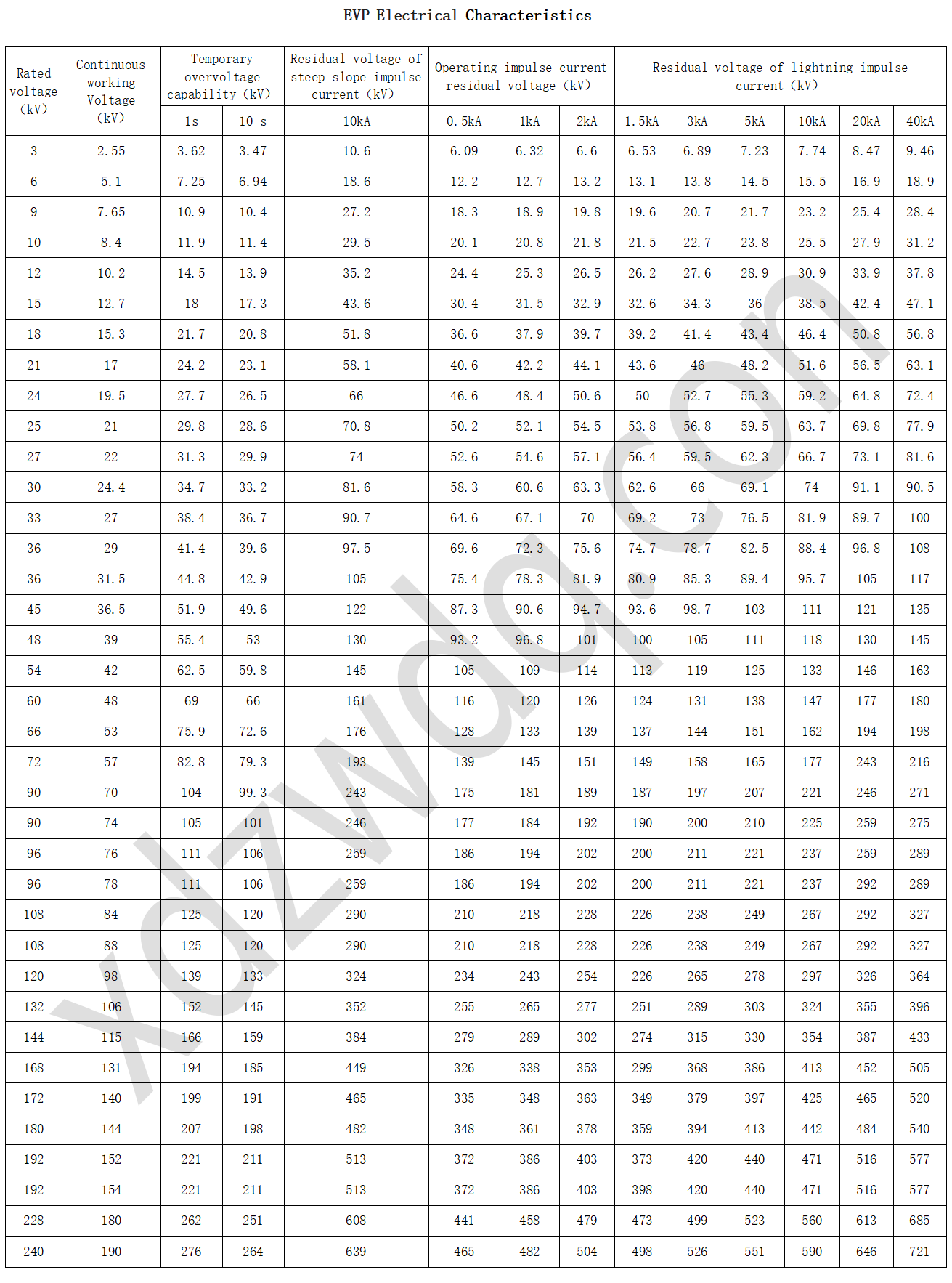

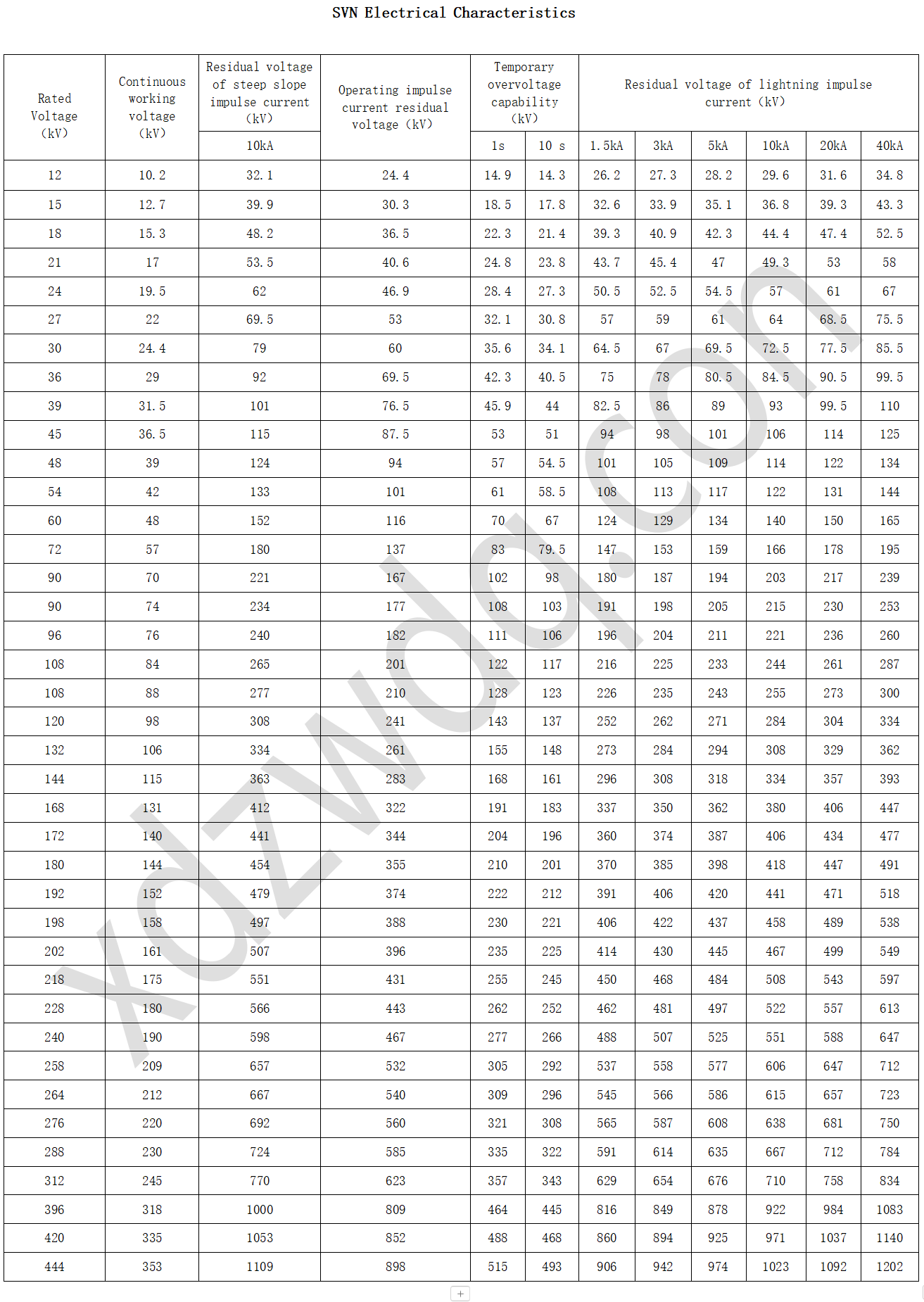

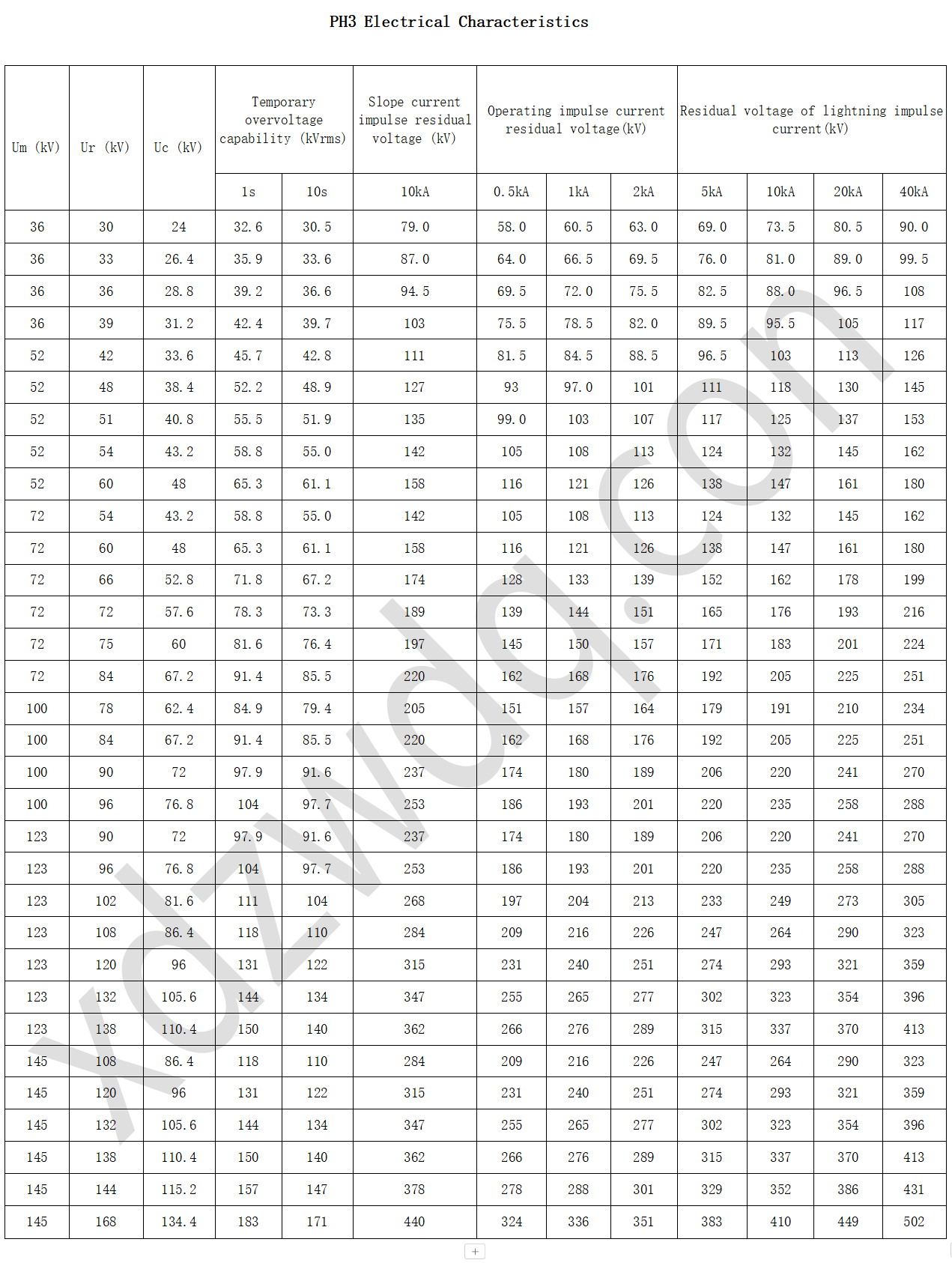

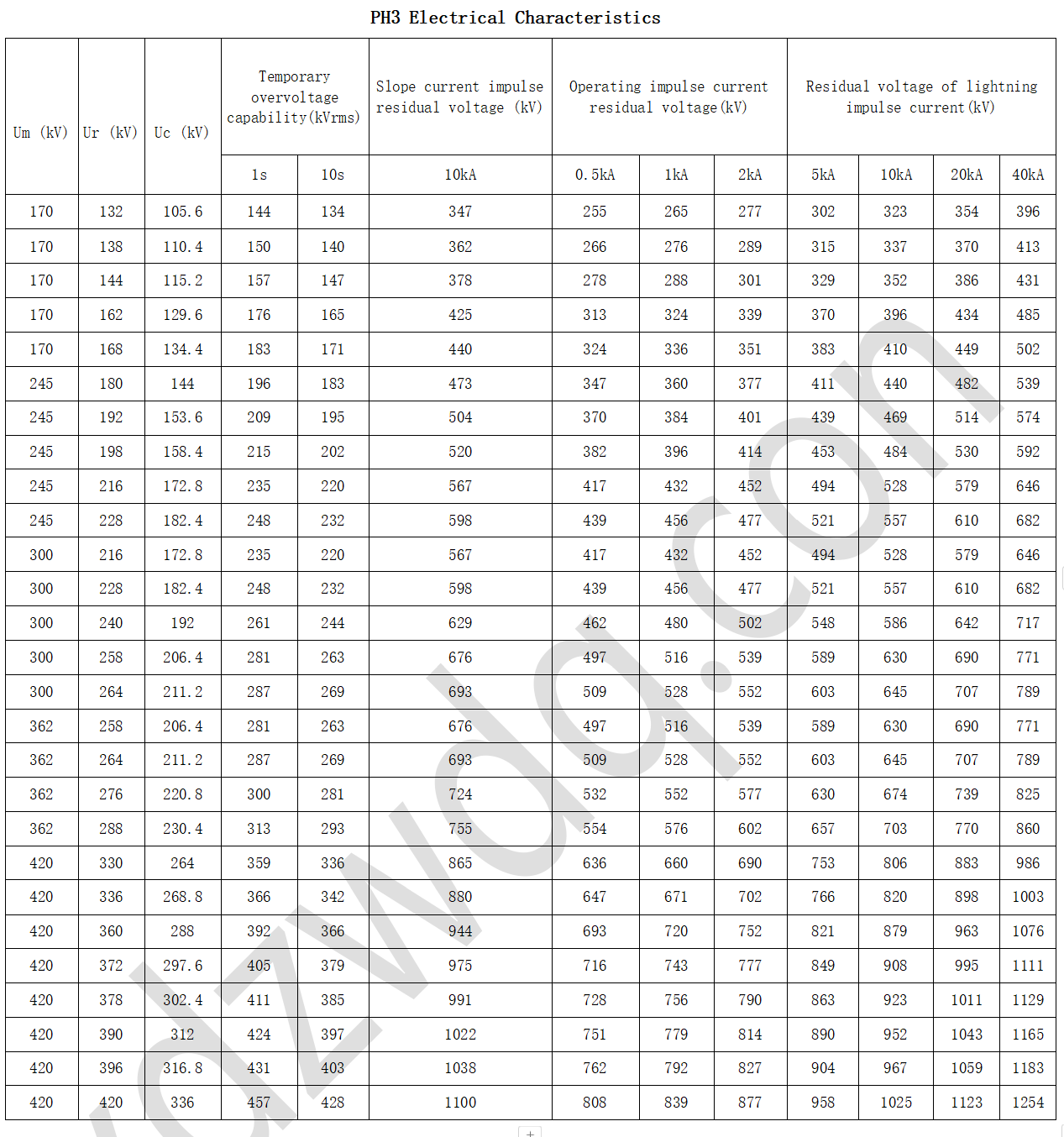

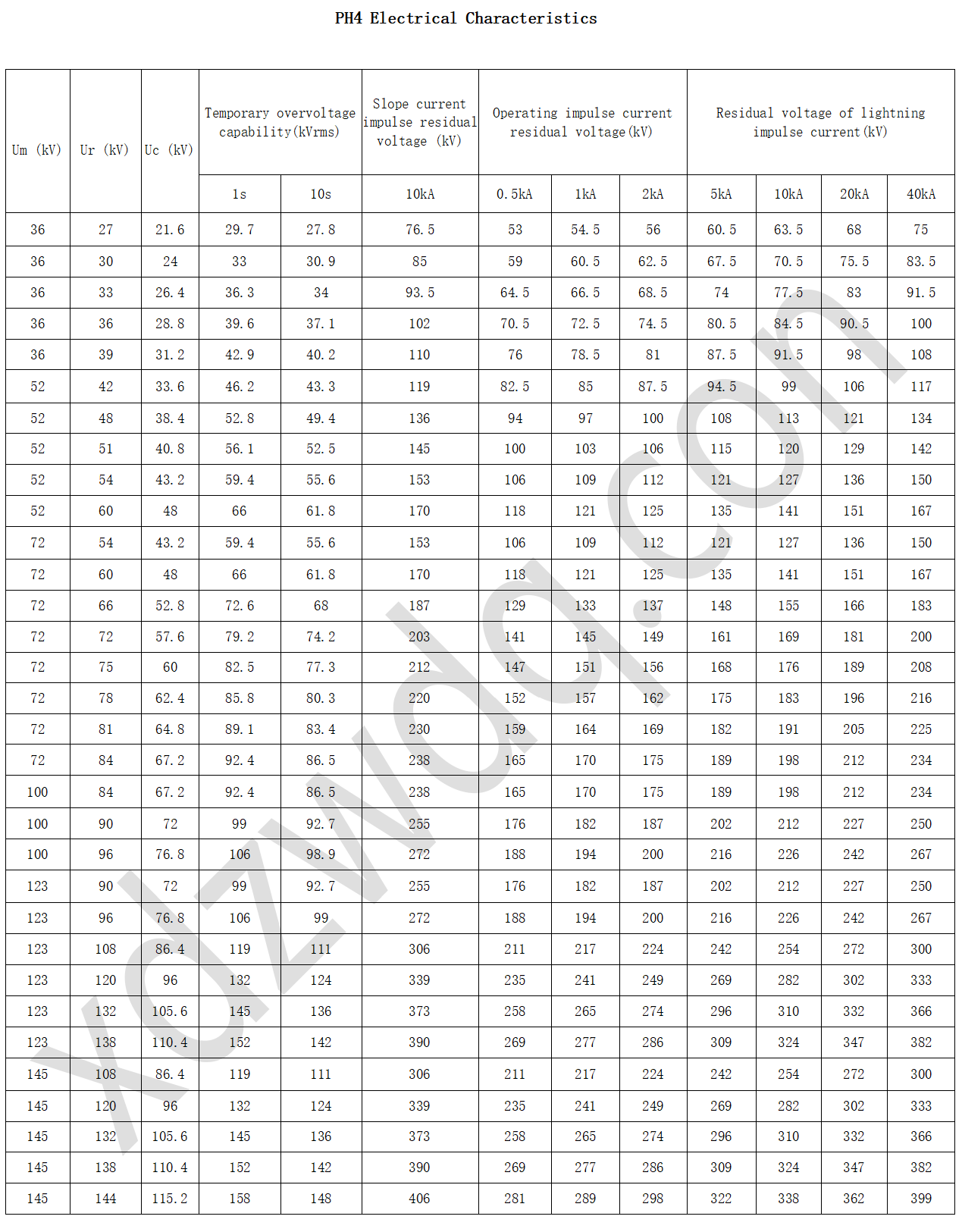

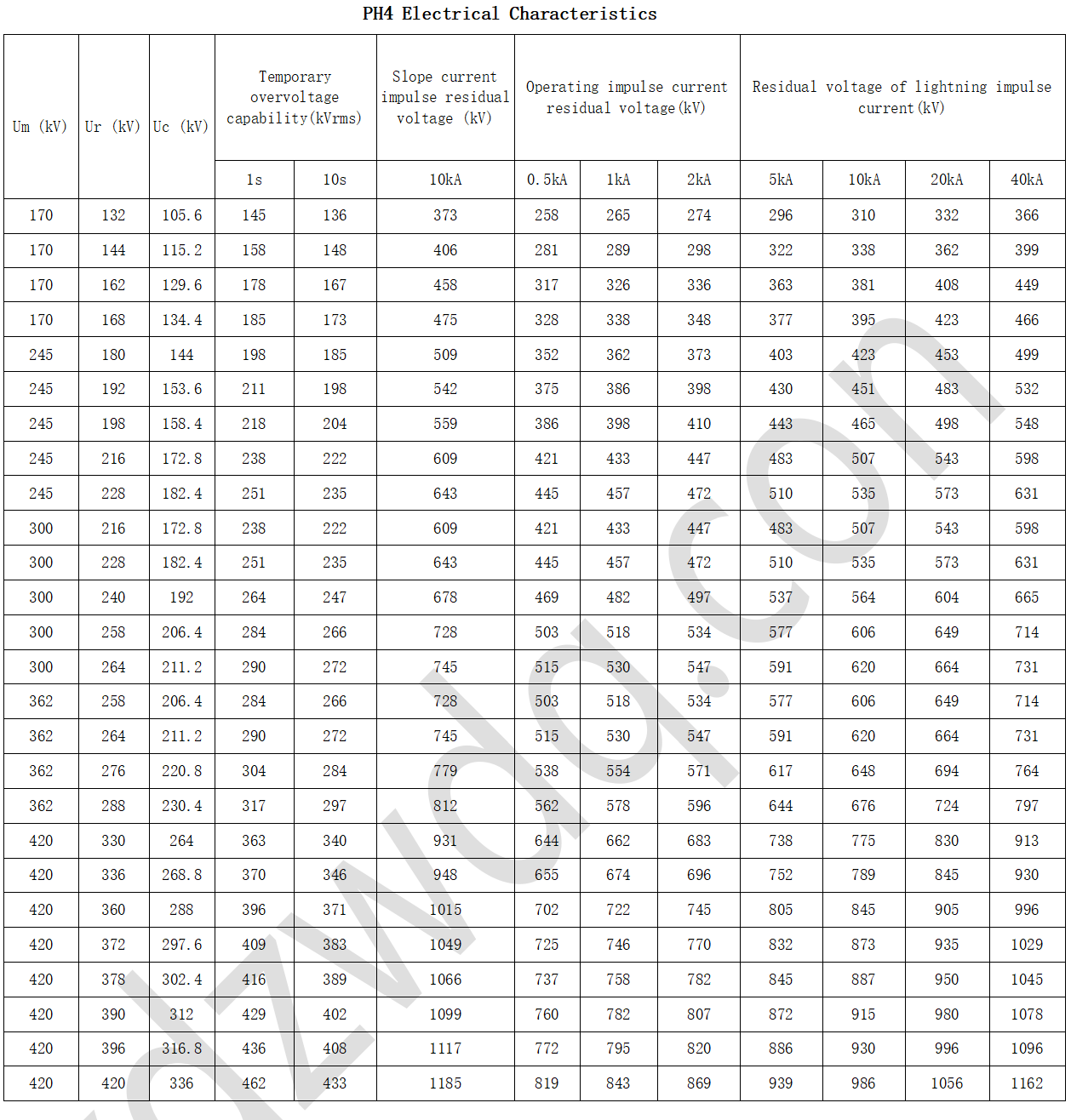

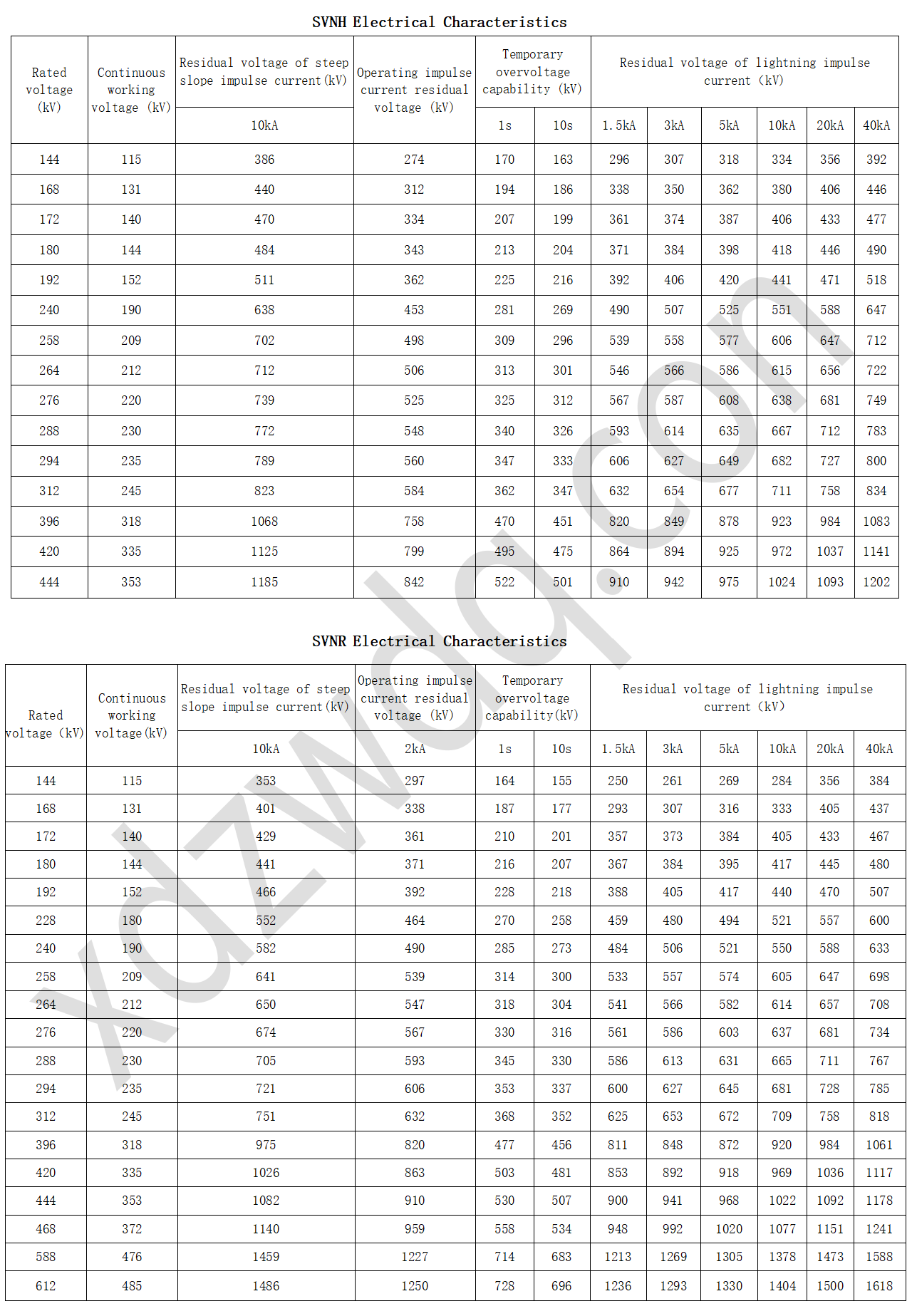

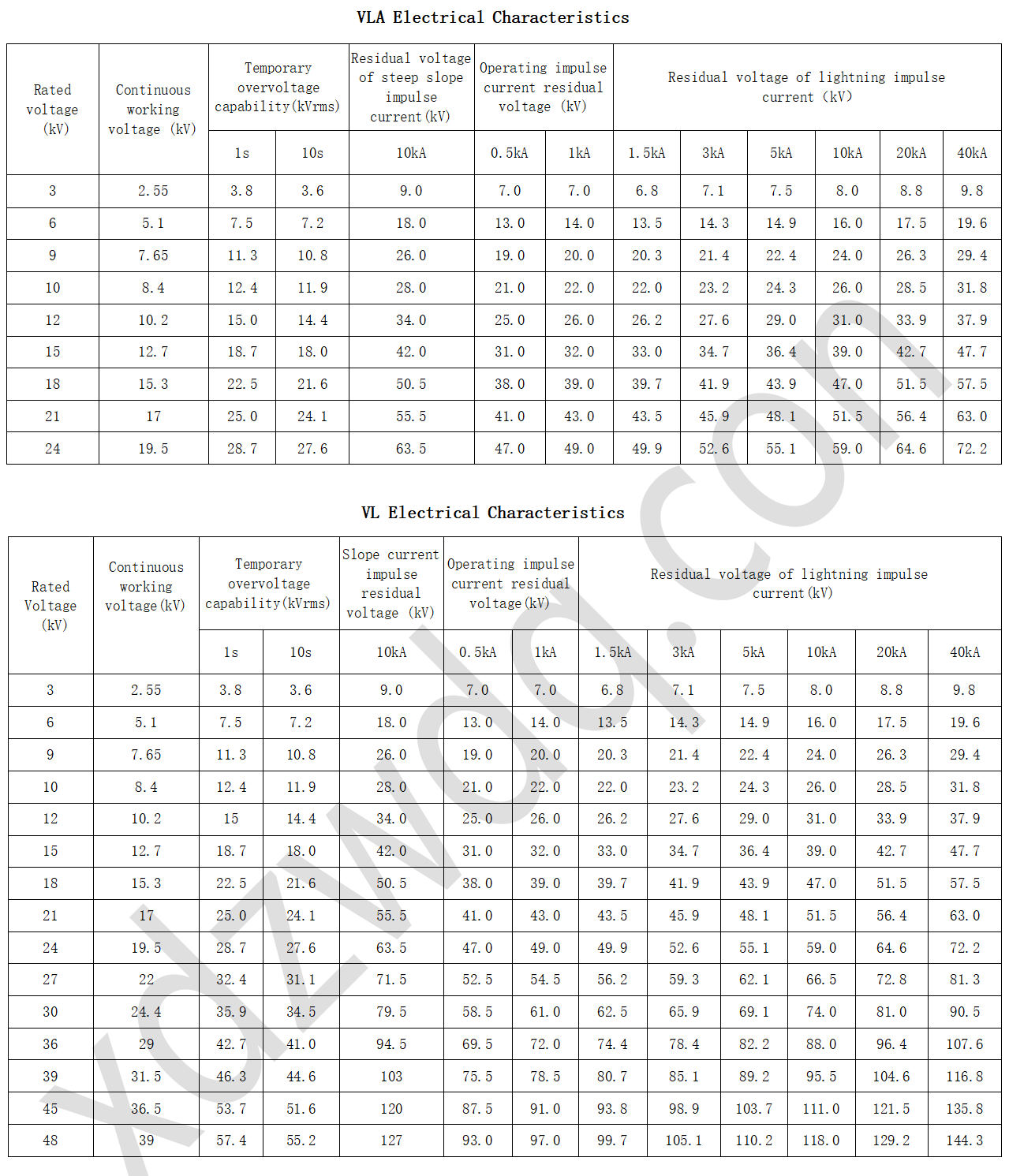

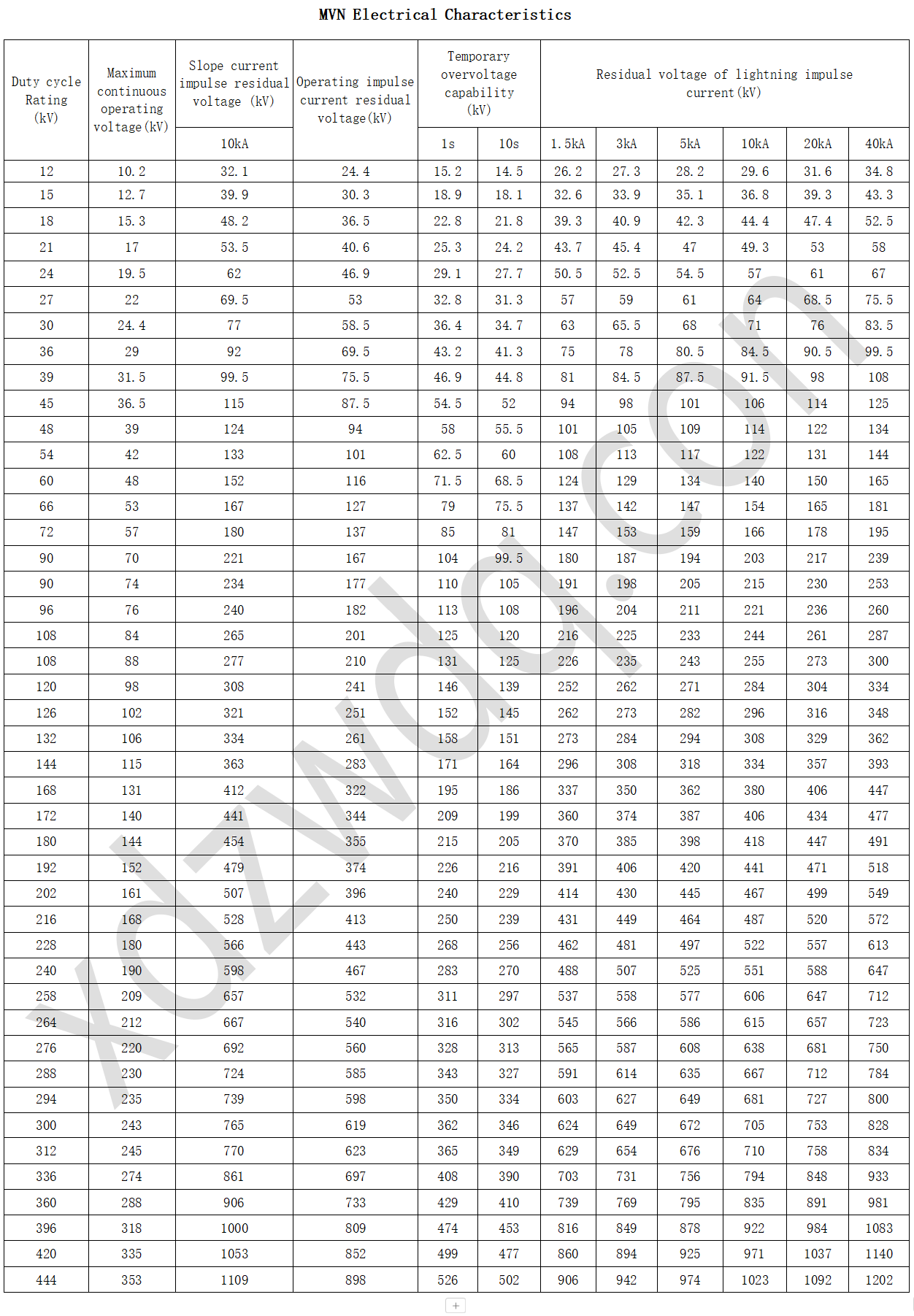

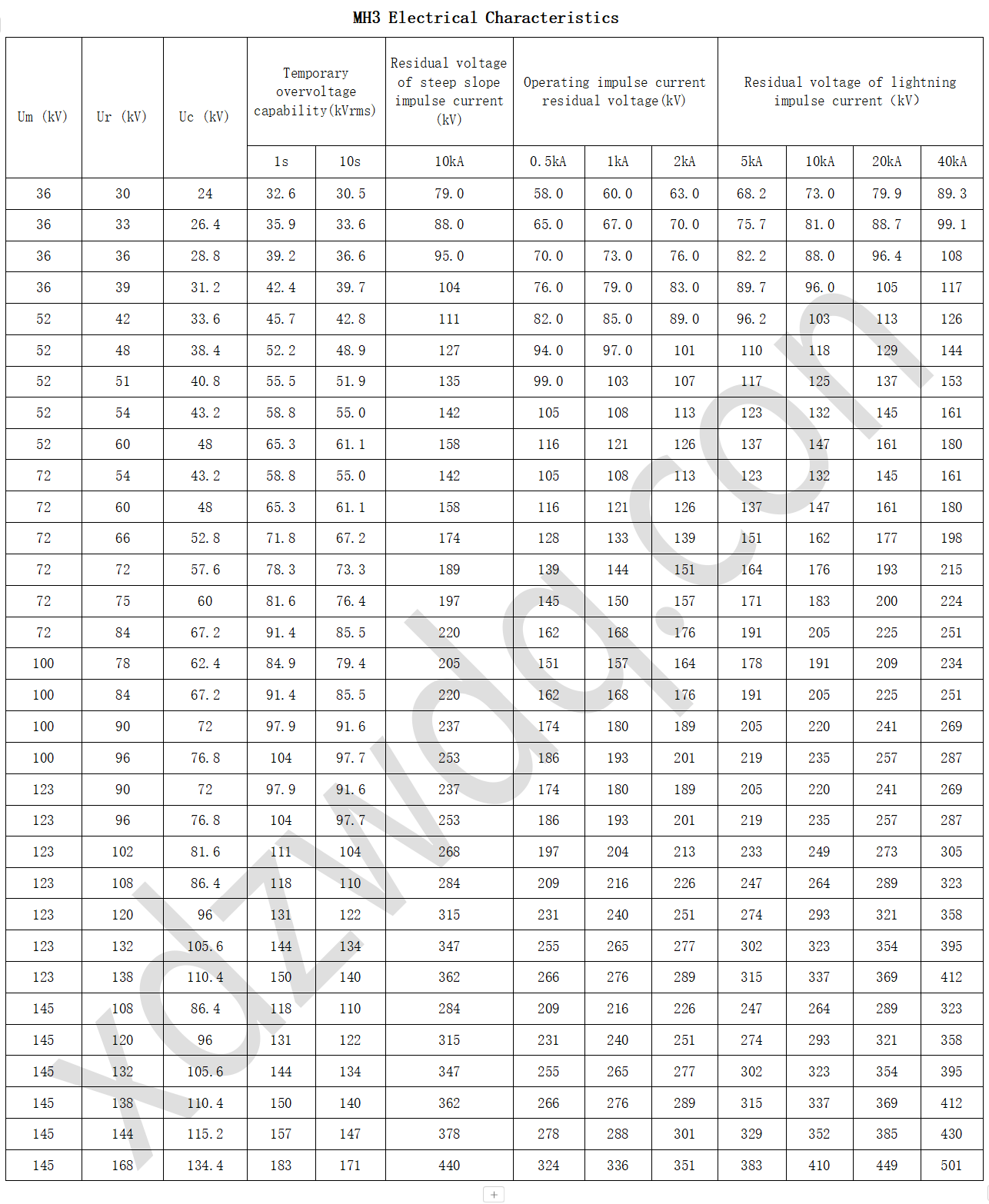

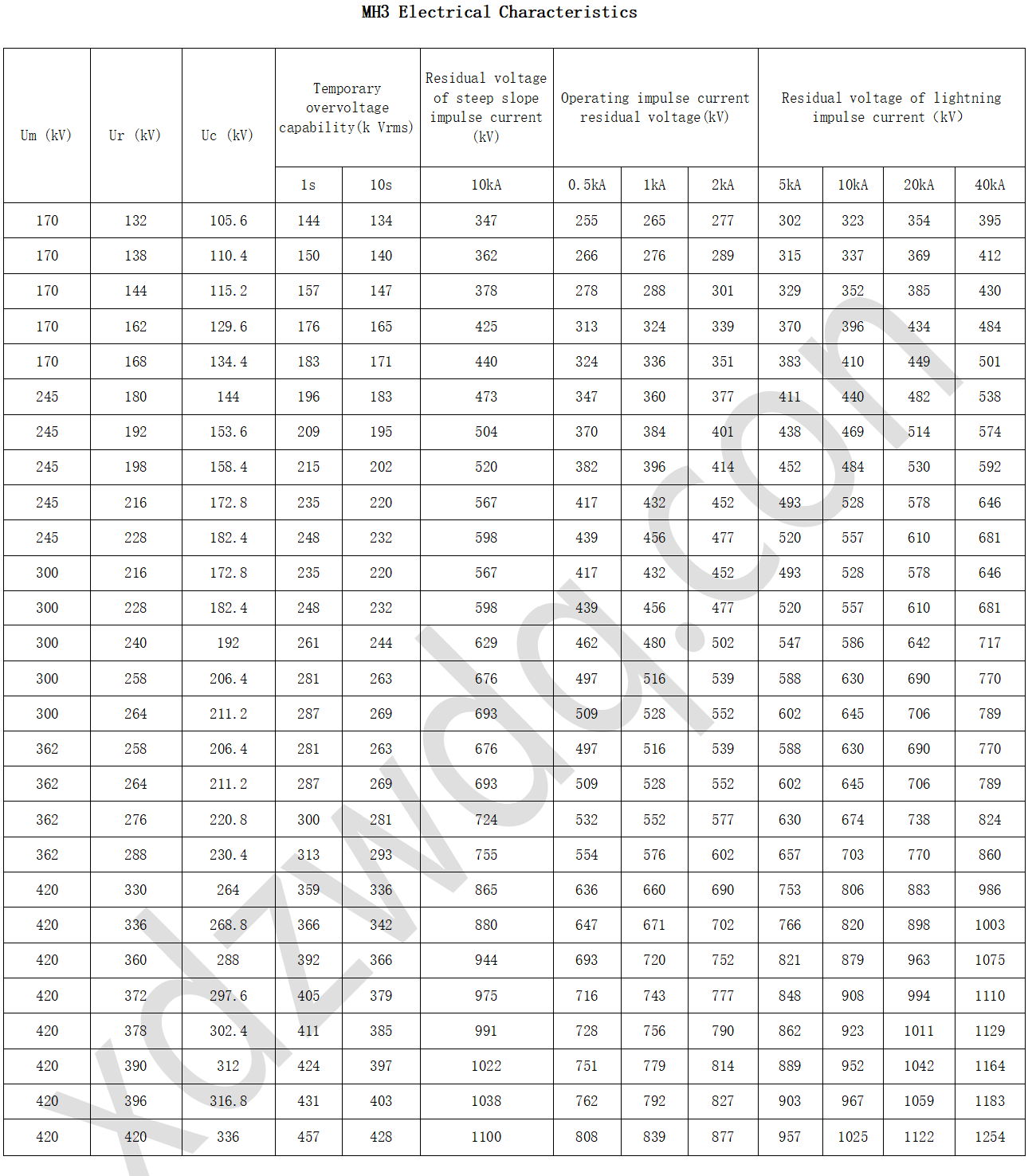

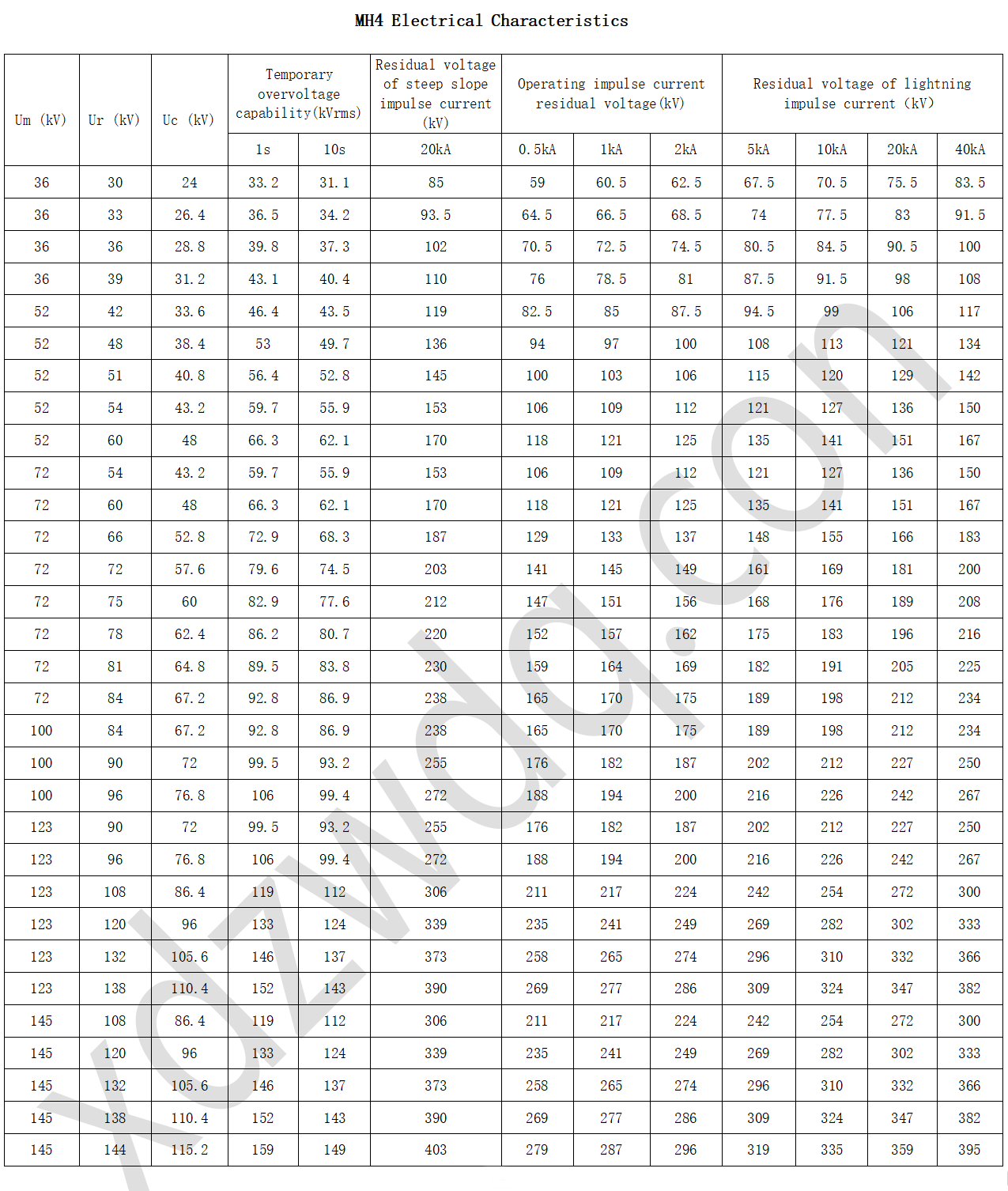

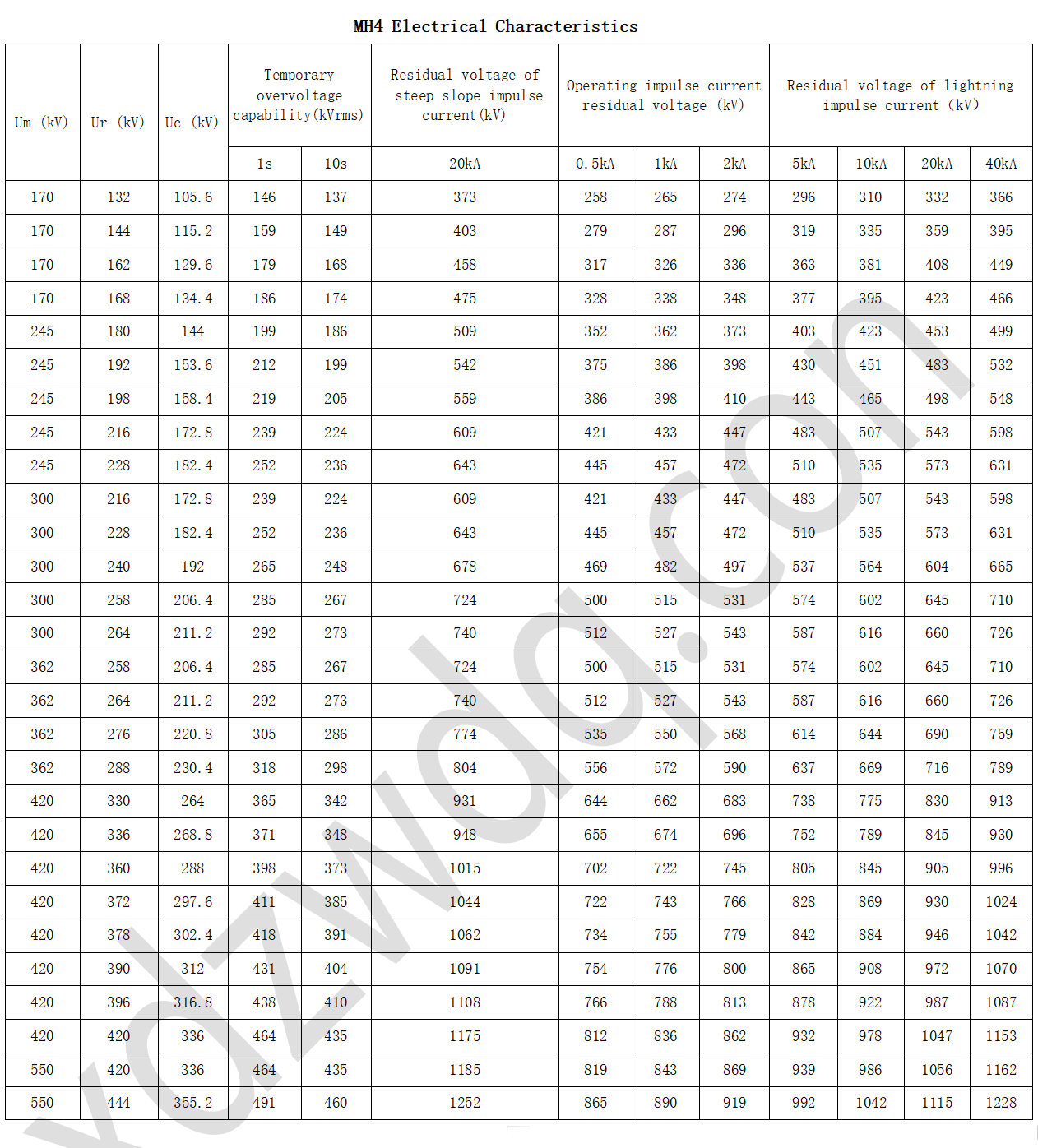

7. Technical parameters

SL=Low Voltage, SM=Medium Voltage, SH=High Voltage

Address: No. 28, Zhaojiabao Industrial Park, Sanqiao, Fengdong New City, Xi'an, China

Phone: 0086029-84591288 Fax: 0086029-33589086

Website: http://www.xdzwdq.com

Email: xdzwdq@ 163.com

Technical Services: 1067522913@qq.com

after-sale service: 2095568013@qq.com

After sales hotline: 180 8913 0344