1. Purpose:

As a special accessory of lightning arresters, thermal explosive disconnectors are used in series with lightning arresters to protect the safe operation of various 6kV-10kV distribution lightning arresters and 35kV-220kV line type gapless lightning arresters (including protection cables and power station type suspension installations). Its working principle is to promptly remove the lightning arrester from the power transmission system when it deteriorates, is about to explode, endangers electrical equipment and personal safety, and leads to a ground short circuit causing switch tripping and power outage accidents. When the lightning arrester is working normally, the disconnector does not move and is in a conducting state. After the detachment device is activated, it can provide clear identification for the faulty lightning arrester, facilitating the rapid detection of the fault point, timely maintenance and replacement, making the lightning arrester meet the requirements of "maintenance free" use, and improving the stability and safety of the power system operation.

2. Scope of use

1. Power frequency not less than 48Hz and not exceeding 62Hz:

2. Altitude not exceeding 3000 meters:

3. Operating environment temperature -40 ° C to 50 ° C:

4. Suitable for outdoor use.

3. Definition of Detacher

A device called a disconnector is used to disconnect the lightning arrester leads from the system in the event of a lightning arrester failure, in order to eliminate continuous faults in the system and provide a visible indication (partition gap) of the faulty lightning arrester. Without the ability to cut off fault currents, it may not be possible to completely prevent 100% lightning arrester explosions, but rather to reduce the risk of lightning arrester explosions by more than 90%.

Separators have been in use abroad for over ten years, while they have only been used and manufactured domestically for nearly ten years and have been exported; It is used in conjunction with lightning arresters, fully leveraging the advantages of zinc oxide lightning arresters, making it an essential component for lightning arresters.

4. Types of Separators

There are generally three types of disconnectors:

The first type is hot melt,

When the zinc oxide lightning arrester malfunctions, the main manifestation is an increase in the current flowing through the valve plate, causing the valve plate group to be in a heating state. Due to the negative temperature coefficient of the valve plate group, the heating causes a decrease in equivalent resistance, which in turn exacerbates the heating, forming a vicious cycle. In this way, the working state of the lightning arrester is directly transmitted to the disconnector in the form of temperature, and the power frequency current is used to generate heat through itself. When this temperature reaches the design value of the disconnector, its low melting point alloy melts, and the disconnector acts to disconnect the lightning arrester from the grounding wire, cutting off the faulty lightning arrester from operation and providing a clear signal to the inspection personnel. This provides a practical and feasible technical measure for achieving "state maintenance" of oxidation lightning arrester.

The second type is thermal explosion,

When the zinc oxide lightning arrester malfunctions, it is mainly manifested as an increase in the current flowing through the valve plate, which uses the power frequency current to generate an arc through itself, igniting the explosive material, causing it to insert into the bolt and explode. The detachment device acts to disconnect the lightning arrester from the grounding wire, cutting off the faulty lightning arrester from operation and providing a clear signal to the inspection personnel, providing practical and feasible technical measures for achieving "state maintenance" of the oxide lightning arrester.

The third type is the composite type, which is a detachment device made by integrating the principles of hot melt and thermal explosion. The outer shell is protected by silicone rubber, effectively avoiding secondary damage to other equipment when it is in operation.

3、 The structure of the disconnector:

Hot melt release device, when the low melting point alloy melts, the insertion end of the release device separates from the release device housing under the action of the release spring elasticity, achieving the purpose of being far away from the power source.

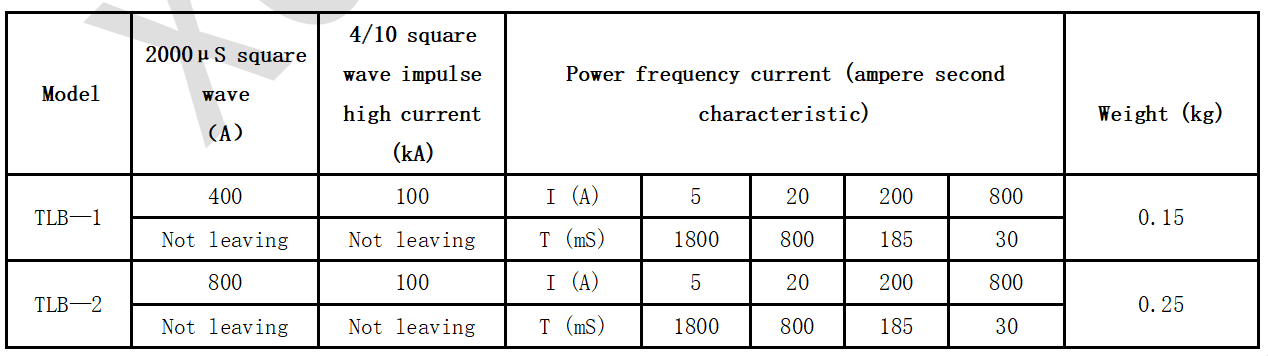

4、 Characteristic parameters of the disconnector:

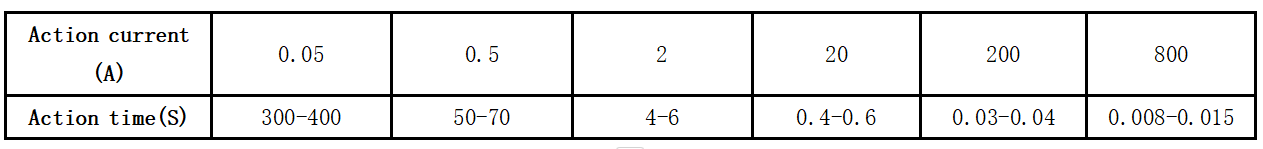

The disconnector does not operate when lightning surge current passes through, but quickly melts and disconnects from the power supply when power frequency current passes through.

Action current and time of disconnector

5. Advantages of Separators

(1) The current range is wide, and combined with the characteristics of China's power grid, it can be disconnected at both large power frequency fault currents (>50A) and small fault currents (50mA).

(2) The fast disengagement speed can be matched with the reclosing function of the circuit breaker, which is not only suitable for various voltage levels and types of lightning arresters, but also for different grounding systems (neutral grounded and ungrounded systems).

(3) Strong impact resistance, it does not move under 2ms square wave and 4/10 μ s high current impact.

(4) The TLB-5 type has high mechanical strength and good sealing performance before detonation, and can be used with lightning arresters below 35KV. The TLB-6 type can be used with lightning arresters between 35-220kV.

(5) Easy to install and replace threaded external interfaces, reliable and convenient to connect in series with lightning arresters, and extremely easy to replace once disconnected. The detachable device is cheap, easy to replace, and brings safe and reliable operation.

6. Selection of Separators

The general selection method is as follows: for small grounding short-circuit current systems, TLB1-1 type disconnectors are selected;

The TLB-2 type disconnector is selected for the high grounding short-circuit current system.

7. Installation instructions

1.Surge arresters with voltage levels of 10kV and below shall be installed on a trailer. The lightning arrester is fixed on the original installation position of the lightning arrester through a bracket, and the disconnector is installed on the lower terminal of the lightning arrester. The grounding point of the disconnector tower is connected with a soft copper wire to ensure sufficient insulation distance after the lightning arrester body is separated.

2.35kV~220kV line type gapless lightning arrester (including protective cables and power station type suspension installation, the disconnector is directly installed on the lower terminal of the lightning arrester, and the connecting wire adopts ¢ 10 hard aluminum wire. The length is selected from 300mm~900mm according to the voltage level (self provided), and connected to the high-voltage line, which can effectively prevent new fault hazards caused by the swinging of the connecting wire after the disconnector is disconnected.

3. 35-110kV power station type lightning arrester (pedestal installation), the disconnector is connected to the high-voltage wire through a wire clamp, and the disconnector is connected to the lightning arrester through braided soft copper wire.

4. The size of the upper screw hole and lower terminal of the disconnector can be related to the size of the lightning arrester wiring terminal.

8. Precautions for using the disconnector

The grounding terminal of the disconnector must use copper multi strand flexible wire with a cross-sectional area greater than 10mm ².

The disconnector used for lightning arresters in transmission lines must be connected to the conductor (power end).

The detachment device and lightning arrester should not be installed on the same axis.

The installation of the disconnector should enable it to move freely and form sufficient air gap, so that the faulty and damaged lightning arrester can be reliably isolated from the system, thereby ensuring that it does not affect the normal operation of the system.